Hydroelectric power plant with run-of-river water

by Frosio Next

April 2023

A hydroelectric power plant converts hydropower into electricity. But how does it work? The potential energy of a watercourse, natural or artificial, is used, placed at a higher altitude than the mechanical organs of energy transformation, i.e. the turbines of the plant.

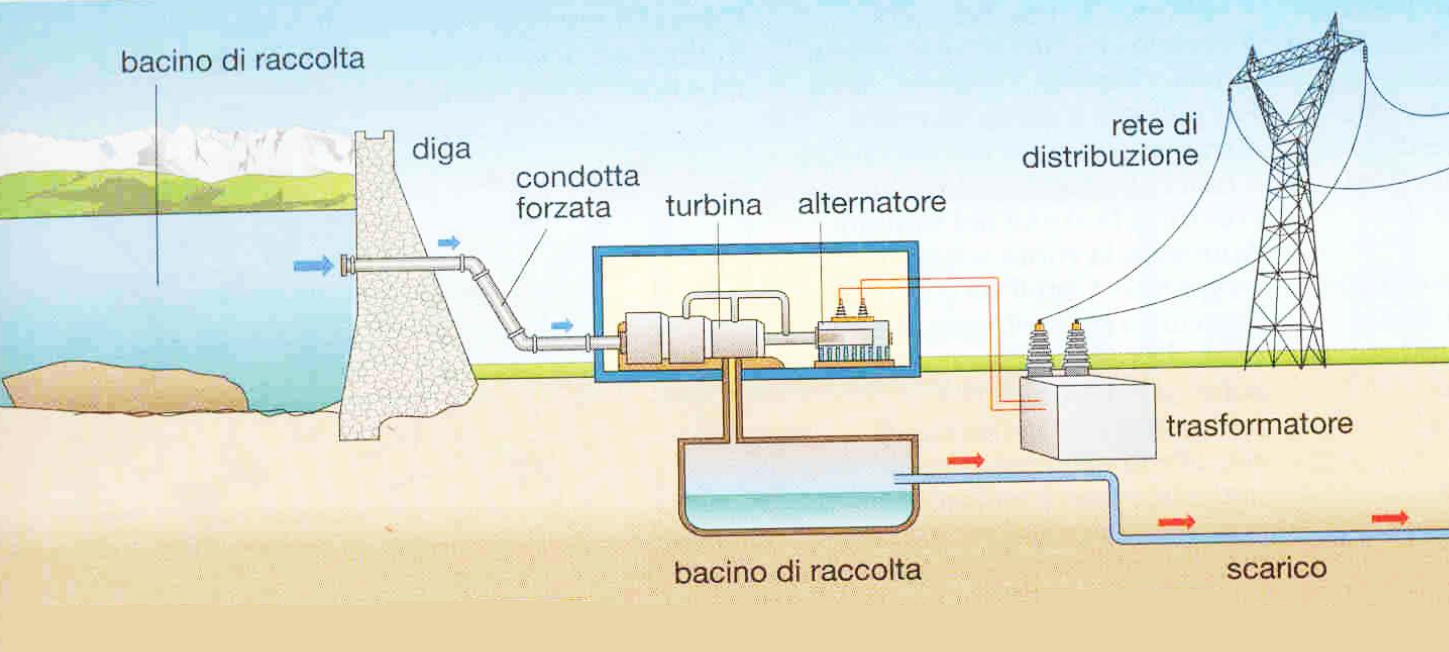

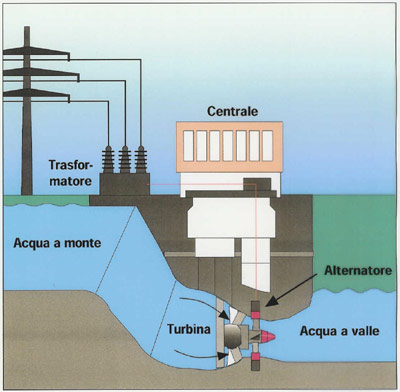

As shown in the image below, thefunctional schema includes a dam or traverse, also known as dam works, which intercept the watercourse, creating a reservoir that can be a reservoir or a hydroelectric basin. Subsequently, the water is conveyed into loading tanks through channels and derivation tunnels (adduction works), and through pipelines, it is directed towards the hydroelectric turbines.

The mechanical energyexerted by the water drives the turbines, and from these flows until it reaches a discharge channel, through which it is returned to the watercourse. Connected to the turbine is the alternator, i.e. a rotating electric generator, which transformsthe mechanical energy received from the turbine into electrical energy. The electricity thus obtained, before being conveyed into the transmission lines, passes through a transformer, which reduces the current intensity by raising the voltage.

Once it arrivesat the place of use, before being used, the energy passes back into a transformer, which this time raises the current intensity and lowers the voltage, to make it suitable for industrial, commercial or domestic uses.

How a hydroelectric power plant with run-of-river water works?

Hydroelectric plants are divided into three macro categories, depending on the type of plant used: run-of-river power plants, basin plants and storage plants.

We analyze below thehypology of run-of-river hydroelectric plant.

In run-of-river power plants, such as dicand the name itself, the natural flow of a watercourse located on two different levels is used. These are plants that are positioned near a river or stream, whose water is partly or completely channeled towards a loading basin without the aid of penstocks. From this basin, then, the water is drained through a channel and towards a plane positioned a little lower where it reaches the turbines. Along the way between the highest and lowest point, the water passes through the hydroelectric turbine, driving the blades and reducingenergy. Finally, the water is returned to the river or stream.

Therefore, the power of a run-of-river hydroelectric plant depends mainly on the speed of the water in the passage from one level to another, the so-called jump, and on the flow rate of the watercourse.

River designs are significantly different in design and appearance than conventional hydroelectric designs. In fact, traditional hydroelectric dams store huge amounts of water in reservoirs, sometimes flooding vast tracts of land. In contrast, run-of-river projects do not have the reservoirs and therefore cause lower environmental impacts.

Sizing of a run-of-river system

The sizing of awater-flowing system depends on many factors, first of all is the availability of the water resource, which can be detected through a careful reading of the auction heights, or the water level with respect to the threshold of a tram. Next, it is necessary to evaluate the size of the implant. In fact, by sizing the system on the maximum flow rate of the watercourse, it would be possible to fully exploit the energy made available, but the plant would work for a long time at partial load causing a number of equivalent hours at very low nominal operation.

On the other hand, by dimensioning the plant for the minimum flow rate of the watercourse, it would work for most of the year at its maximum power, but doing so would give upa large part of the energy potential of the watercourse.

In a preliminary study, therefore, the nominal flow rate could be chosen arbitrarily trying to maximize the economic profitability index. On the basis of the value chosen, thecomponents of the plant will be dimensioned and the corresponding costs, the energy that can be produced, revenues, cash flows and finally the net present value (NPV) will be calculated.

Advantages & Disadvantages

If carefully developed, run-of-river hydroelectric projects can create sustainable energy while minimizing impact on the surrounding environment and nearby communities.

But what are the main consequences?

Cleaner energy and less greenhouse gases

Like all hydroelectric energy, run-of-river energy exploits the natural potential energy of water. This eliminates the need to burn fuels to generate electricity, thus avoiding the release of gases such as methane and carbonicnidride caused by the decomposition of burnt organic matter.

Less flooding

With the absence of a reservoir, flooding is avoided. As a result, any neighboring communities can continue to live near the river andexisting bitats are not changed.

As for the limits of a run-of-river hydroelectric plant, first of all is the natural flow of the river. In fact, in some periods of the year it will be greater, and therefore it will be possible to produce more energy, in others it will be less. Wanting to take full advantage of the resource, it is necessary to create a barrier in a suitable section of the river, in order to generate a lake, which can accumulate water in rainy periods and then have it available in the perior little rain. Energy cannot coordinate electricity production to meet consumer demand, which is why run-of-river plants are considered an ” unstable” source of energy, having little or no storage capacity. Finally, the diversion of large amounts of river water reduces the flow rates of the river, affecting the speed and depth of the water. This reduces the quality of habitat for fish and aquatic organisms causing reduced flows that, especially in summer, bring excessively warm water.

Find out more news

The hydroelectric concession in Italy

Discover the latest news related to the topic of hydroelectric concessions in Italy

FROSIO NEXT, not only hydropower plants: construction of a revetment wall in the riverbed of Mella river

FROSIO NEXT carried out the design and the construction of a revetment wall in the riverbed of the Mella river in order to protect the foundations of some buildings in Gardone Val Trompia (BS).

Hydro 2023: Frosio Next in Edinburgh, Scotland

Frosio Next at Hydro 2023 in Edinburgh, Scotland

Contact us

Do you want to start a great project with us?

Fill the form and get in touch with us.